-

07 05 2024

07 05 2024Horizontal Fermentation Tank - LANE Machinery Groups

Horizontal fermentation tank working principle: 1) Collect livestock and poultry manure back from farms and straw, edible fungus dregs and other wastes from rural areas, air-dry and crush them. 2) According to the fixed formula ratio of livestock and poultry manure 70%, smoke end, straw 30% mixed to join the high-speed fermentation equipment

Get Price -

07 05 2024

07 05 2024Art of Fermentation: A Comprehensive Guide to Fermenting Tanks

May 4, 2023 · They provide a controlled environment where yeast can transform sugars into alcohol and carbon dioxide, resulting in the desired end product. In this article, we’ll explore the various types of fermenting tanks, their materials, and the factors to consider when choosing the right one for your needs.

Get Price -

07 05 2024

07 05 2024Comprehensive review on agricultural waste utilization and

The fermentation cycle of fermentation tank aerobic composting is 11–13 days. Horizontal fermentation equipment is easy to control and is mainly used for small and medium-scale composting. In contrast, vertical fermentation equipment has a large processing capacity and is mainly used for large-scale composting plants, shown in “Fig. 10b ”.

Get Price -

07 05 2024

07 05 2024How to Utilize Manure Fermentation Equipment for Farm Waste

Dec 11, 2023 · December 11, 2023. News. Livestock and poultry manure drying and fermentation machines are specialized integrated equipment for handling organic waste such as livestock and poultry manure, domestic sludge, and kitchen scraps. The primary purpose is to utilize the activity of microorganisms to biologically decompose and mature organic matter in

Get Price -

07 05 2024

07 05 2024Available Technical Options for Manure Management in

Apr 14, 2023 · When fermentation was unstable or incomplete, an immediate increase of coliforms occurred, and in some cases, survival of Salmonella was observed. Few changes were observed in other bacterial parameters examined. Sulphite-reducing clostridia usually survived up to 10 3 colony-forming units (CFU) per ml.

Get Price -

07 05 2024

07 05 2024In Vessel Composting Systems for Organic Fertilizer

Considering its closed design and high automation, our In tank composting system has high efficiency in speeding up composting. Commonly, it takes about 20-25 days when your animal manure becomes good organic fertilizer powder, if you use compost turning machines to turn your compost. However, our fermentation tank makes it possible to finish

Get Price -

07 05 2024

07 05 2024Sustainable nutrient recovery from animal manure: A review of

Sep 15, 2021 · 1. Introduction1.1. Livestock waste production and the resulting environmental impact. According to a recent report, world population has doubled in the last 40 years and reached 7.7 billion in 2019; with a current growth rate of 1.08% per year the population is estimated to reach 9 billion by 2037 (Max et al., 2019).

Get Price -

07 05 2024

07 05 2024Sustainability | Free Full-Text | Optimization and Experiment

Jul 21, 2023 · The composting fermentation system, also called the fermentation silo, consists primarily of fermentation tanks, mixers, reclaiming devices, and deodorization devices. The ventilation heating system, also known as the hot gas device, includes an air pump, heating box, electric heating pipe, and ventilation pipeline.

Get Price -

07 05 2024

07 05 2024Organic Fertilizer Production Poultry Manure Compost Tanks

Organic Fertilizer Production Poultry Manure Compost Tanks Fermentation Equipment, Find Details and Price about Fermentation Tank Fermentation Tank for Sale from Organic Fertilizer Production Poultry Manure Compost Tanks Fermentation Equipment - Henan Tongda Heavy Industry Science And Technology Co., Ltd.

Get Price -

07 05 2024

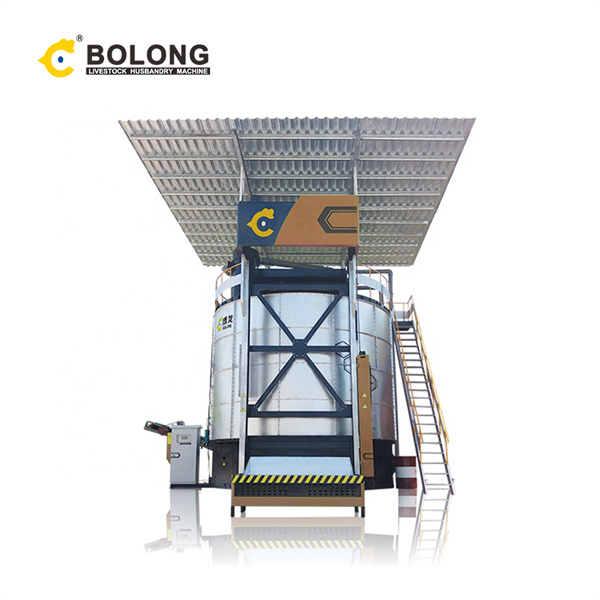

07 05 2024High-Temperature Aerobic Fermentation Tank | Fermentation Tank

The High-temperature aerobic fermentation tank equipment developed by ABC Machinery adopts a fully enclosed design. The fecal fermentation process is not affected by the natural environment, allowing the production of organic fertilizer to meet industrial production standards, preventing the leakage of waste gas generated by fermentation, and eliminating secondary pollution of waste gas

Get Price -

07 05 2024

07 05 2024The Essential Guide to 100-Gallon Fermentation Tanks: Brewing

Apr 2, 2024 · Brewing Excellence: Elevate Your Craft with Cedarstone’s 100-Gallon Fermentation Tanks. Cedarstone Industry, LLC introduces the definitive guide to perfecting beverage production with our 100-gallon fermentation tanks, complementing our range of 250-gallon totes.

Get Price -

07 05 2024

07 05 2024Fermentation | Free Full-Text | Microbiological and

May 2, 2023 · Anaerobic digestion of animal manure results in the production of renewable energy (biogas) and nutrient-rich biofertilizer. A further benefit of the technology is decreased greenhouse gas emissions that otherwise occur during manure storage. Since animal manure makes anaerobic digestion cost-efficient and further advance the technology for higher methane yields, it is of utmost importance to

Get Price -

07 05 2024

07 05 2024A Possibility of Functioning Biogas Plant at a Poultry Farm

source of the substrate. The micro-biogas plant includes a fermentation tank with a capacity of 500 m3 and storage of digestate pulp with a capacity of 700 m3. The assumed power biogas plant will generate 112 kW of electric-ity and 120 kW of heat. The installation will operate in a single-stage mesophilic technology (39 ºC), which will

Get Price -

07 05 2024

07 05 2024How to Choose the Right Size Fermentation Tank for Your

Dec 29, 2022 · 1. Production Capacity. One of the most obvious factors to consider when choosing a fermentation tank is the production capacity of your brewery. You want to ensure that you have enough fermentation capacity to meet the demand for your beer, but you also don’t want to waste money on tanks that are too large for your needs.

Get Price -

07 05 2024

07 05 2024Manure fermentation on farm scale in Bathmen - CCS Energie-advies

In fermentation, manure is brought into a heated tank, where bacteria break down a part of the biomass and produce biogas. The digestate is then separated into a thick and thin fraction. Finally, the thin fraction goes to the manure processing plant. CCS Energie-advies has developed the Bio-NP concept specifically for this purpose.

Get Price

English

English

中文简体

中文简体