-

09 05 2024

09 05 2024Organic fertilizer fermentation tank operation process method

2.Increase the temperature to 90°C-100°C by electric heating, then turn off the power for 2 hours, and keep the temperature between 65°C and 80°C. At the same time, the matching stirring system in the fermentation tank stirs at intervals, and the whole fermentation process is completed. It can be produced and processed in about 10 hours.

Get Price -

09 05 2024

09 05 2024Fresh Manure Fermentation Processing - Fertilizer

Oct 30, 2017 · 1.Small capacity organic fertilizer factory processing steps (raw material is fresh manure) 1.1 Add Leaven. 1 kilogram leaven could be added in 10-20 tons fresh manure, because the quantity of leaven is too small. 1 kilogram leaven can be mixed with 100 kilograms rice husk or sawdust. Then add fresh manure evenly. 1.2 Processing.

Get Price -

09 05 2024

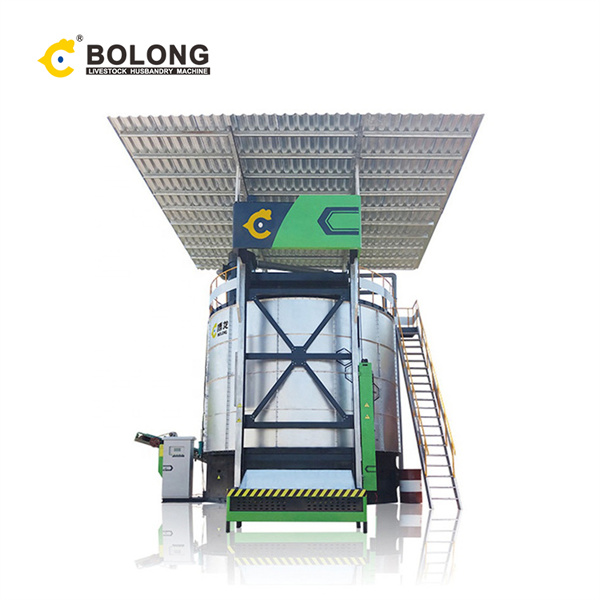

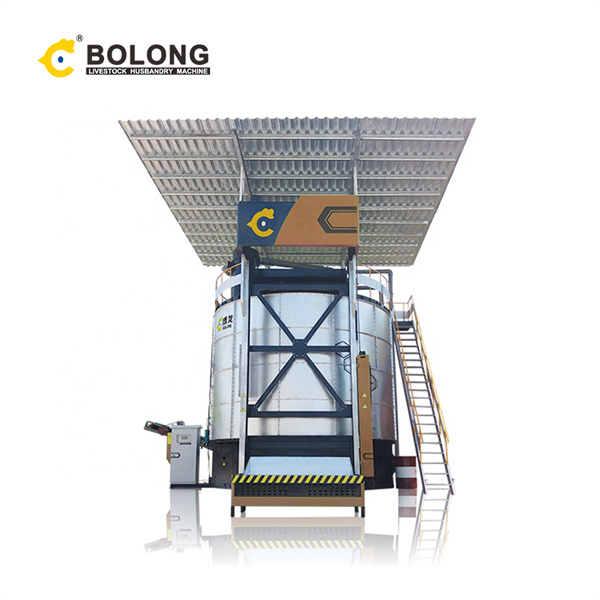

09 05 2024Compost fermentation tank - Zhengzhou Tianci Heavy Industry

Compost fermentation tank. Usage: Compost fermentation for organic fertilizer manure Production capacity: 1-10 tph Product Highlights: High fermentation efficiency and short fermentation cycle Applicable materials: Cattle manure, chicken manure, poultry manure, grass ash, lignite, straw, bean cakes, corn straw etc. Fermentation Maturity Stage

Get Price -

09 05 2024

09 05 2024High-Temperature Aerobic Fermentation Tank | Fermentation Tank

The High-temperature aerobic fermentation tank equipment developed by ABC Machinery adopts a fully enclosed design. The fecal fermentation process is not affected by the natural environment, allowing the production of organic fertilizer to meet industrial production standards, preventing the leakage of waste gas generated by fermentation, and eliminating secondary pollution of waste gas

Get Price -

09 05 2024

09 05 2024State of the Industry Report: Fermentation | GFI

158 total fermentation companies that were focused exclusively or predominantly on alternative proteins by the end of 2023. $4.1 billion all-time investment in companies focused on fermentation for alternative proteins. $515 million invested in 2023 in companies focused on fermentation for alternative proteins.

Get Price -

09 05 2024

09 05 2024The Essential Guide to 100-Gallon Fermentation Tanks: Brewing

Apr 2, 2024 · Cedarstone Industry, LLC introduces the definitive guide to perfecting beverage production with our 100-gallon fermentation tanks, complementing our range of 250-gallon totes. Engineered for precision and consistency, our tanks empower brewers and vintners with unparalleled control over the fermentation process.

Get Price -

09 05 2024

09 05 2024Organic Fertilizer Fermentation Tank | 3 Stages of Fermentation

There are four treatment procedure of the organic fertilizer fermentation tank. Firstly,automatically feeding.Then,you can make material get perfect stage through high-temperature fermentation. After that,material is discharged from your fermenter. Finally,you can put these fermented material into storage. organic tertilizer production tank.

Get Price -

09 05 2024

09 05 2024Biological composting : stacking fermentation, tank

2. The advantages of the "tank fermentation" process are that the whole fermentation process can be strictly controlled, the quality of the produced organic fertilizer products is stable, the production process is clean and tidy, and the environmental pollution is small; the disadvantages are that the initial investment is large, the production cost is high and the production volume is small

Get Price -

09 05 2024

09 05 2024Applied Sciences | Free Full-Text | Development and - MDPI

Jul 27, 2023 · This paper believes cow dung import and export should be based on the fermentation tank’s structural size and target compost amount. The fermentation tank of cow dung composting equipment is regarded as a cylinder, and the corresponding inner cavity diameter and height [29,30,31] can be further determined after the internal volume is known

Get Price -

09 05 2024

09 05 2024Fermentation: A Process for Biofertilizer Production - Springer

Dec 8, 2017 · Fertilizer is a chemical or natural substance added to soil or plant parts to increase the soil fertility and plant growth. As per Fertilizer (Control) Order, 1985 (FCO 1985, amendment November 2009, Ministry of Agriculture, Department of Agriculture and Cooperation, Government of India), there are three types of fertilizers: (1) inorganic fertilizers, inorganic substances of synthetic origin

Get Price -

09 05 2024

09 05 2024Beer Fermentation Tanks - YoLong Brewtech

Jan 19, 2024 · Beer fermentation tanks cover a wide range of sizes from a few barrels to massive volumes over 1000 barrels. Some typical fermenter capacities include: Pilot Systems: 1-3 BBL. Microbreweries: 3-7 BBL, 7-30 BBL. Pub Breweries: 15-30 BBL. Production Breweries: 30-300 BBL, 600-800 BBL, 1000+ BBL.

Get Price -

09 05 2024

09 05 2024Compost Fermentation Tank | Fertilizer Equipment Manfacturer

Usage: Compost fermentation for organic fertilizer manure. Production capacity: 1-10 tph. Product Highlights: High fermentation efficiency and short fermentation cycle. Applicable materials: Cattle manure, chicken manure, poultry manure, grass ash, lignite, straw, bean cakes, corn straw etc. Fermentation Maturity Stage: 4-6 hours.

Get Price -

09 05 2024

09 05 2024Livestock And Poultry Manure Fermentation Tank | Compost

The Animal manure fermentation tank can process organic fertilizer processing of different livestock and poultry manure, food waste, domestic sludge, etc. As long as the moisture content of organic waste is below 65%, there is no need to add any auxiliary materials and it can be put directly into the tank.

Get Price -

09 05 2024

09 05 2024Art of Fermentation: A Comprehensive Guide to Fermenting Tanks

May 4, 2023 · When selecting a fermenting tank, consider the following factors: Type of beverage or food you plan to ferment; Your experience level and skillset; The available space in your brewing or fermenting area; Your budget; The desired capacity of the fermenting tank; The Fermentation Process in Fermenting Tanks

Get Price -

09 05 2024

09 05 2024Fermentation Tank for Sale - organic fertilizer plants

The main structures of fermentation tank include body, mixer, air supply system, material lifting device, control cabinet, hydraulic power station, biological deodorization equipment and sensors of temperature and oxygen concentration. Mixer: The mixer is fixed inside the fermentation tank. It is used for stirring organic waste to realize

Get Price

English

English

中文简体

中文简体