-

26 04 2024

26 04 2024Organic Fertilizer Production | Organic Fertilizer Machine

Specialize in Organic Fertilizer Production. ABC Machinery is a leading manufacturer of organic fertilizer production with CE & ISO certifications. We specializes in the design, development, and production of large-scale equipment such as fermentation tanks, and fertilizer granulators. ABC machinery provide customized solution for organic

Get Price -

26 04 2024

26 04 2024Bio Organic Fertilizer Fermentation Tank

1. High-temperature aerobic fermentation and bio-bacteria technology using with low energy consumption. 2. Closed fermentation, biological deodorization equipment to achieve no secondary pollution. 3. The device body made of stainless special materials to reduce corrosion and long life in Fermentation Tank for Cow Manure. 4.

Get Price -

26 04 2024

26 04 2024Manure Fermentation - Jongia Mixing Technology

The process involves the use of solid-state fermentation, where the manure is mixed with other organic wastes such as paper sludge and dried to a moisture content of 30-40%. The mixture is then loaded into fermentation tanks, where the fermentation process takes place.

Get Price -

26 04 2024

26 04 2024Applied Sciences | Free Full-Text | Development and - MDPI

Jul 27, 2023 · Traditional cow manure composting equipment often lacks ventilation, heating, and real-time monitoring and adjustment capabilities, hindering manure maturation and proper utilization of compost, moisture reduction, and optimal environmental conditions for microbial activity.

Get Price -

26 04 2024

26 04 2024Development and Evaluation of Cow Dung Composting Equipment

Jul 27, 2023 · 2.1.1. Design of Cattle Manure Fermentation Tank Based on Target Compost Amount In the operation of cow dung composting equipment, the design of inlet and outlet is very important. This paper believes cow dung import and export should be based on the fermentation tank’s structural size and target compost amount. The fermentation tank of

Get Price -

26 04 2024

26 04 2024manure fermentation tank – Shovel

Jan 5, 2022 · Also look at the upper tank, which should be constructed with waterproof materials, and it should also have an automatic bucket elevator and heat exchange system. After assessing all of the ones that you can find, you will eventually locate the very best animal manure fermentation tank for this exact purpose.

Get Price -

26 04 2024

26 04 2024The Mixed Fermentation Technology of Solid Wastes of

Apr 16, 2020 · The measurement time is set at 17:00 p.m. every day, shake the fermentation tank manually for 30 s to break the crust on the surface of fermentation raw materials in the fermentation tank and release the generated gas. The volume of water in the water collecting barrel was measured with the cylinder, which is the biogas output of the day.

Get Price -

26 04 2024

26 04 2024Manure composting system | composting process &

For manure composting system, you can know about it from the following aspects, including composting process, composting , machines used in composting, composting conditions, and deep processing after composting. What’s the complete composting process to convert manure to fertilizer?

Get Price -

26 04 2024

26 04 2024Industrial Fermentation Tank for sale for Fertilizer Plant

First you should calibrate the pH electrode and dissolved oxygen electrode. Fertilizer sterilization. Put the medium into the tank as needed. After sealed by the requirement, small fermentation tank (5 l) can be put the tank body in large sterilization pot sterilization (115 ℃, 30 minutes). A large fermentation tank (10 l and above) should

Get Price -

26 04 2024

26 04 2024A Design of a Solar Fermentation System on Chicken Manure by

Nov 12, 2021 · The fermenter section is horizontally matched with a water tank and a stirring blade, and the manure and decomposing bacteria are placed therein for fermentation. The temperature control part is divided into a solar heating and a backup gas-fuel water heater to make the fermenter reach a constant temperature.

Get Price -

26 04 2024

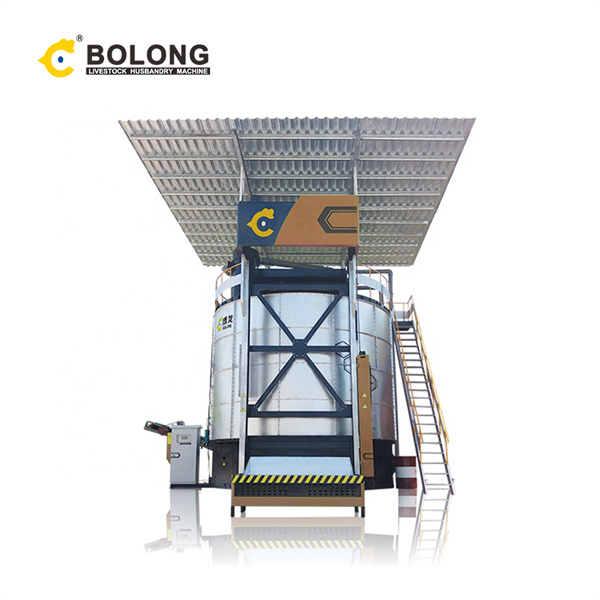

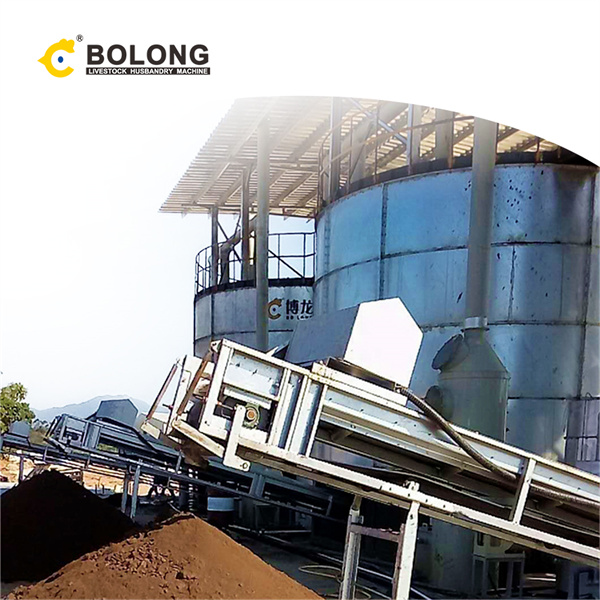

26 04 2024Livestock And Poultry Manure Fermentation Tank | Compost

Advantages of Animal manure fermentation tank. 1. Drive Design: Hydraulic drive for high thrust, ensuring stable operation with high-temperature organic materials, and low maintenance costs. 2. Thermal Insulation: Polyurethane insulation for year-round fermentation, minimizing external influence. 3.

Get Price -

26 04 2024

26 04 2024Fermentation tank | Working princile and constructure of

The main structures of fermentation tank include body, mixer, air supply system, material lifting device, control cabinet, hydraulic power station, biological deodorization equipment and sensors of temperature and oxygen concentration. Mixer: The mixer is fixed inside the fermentation tank. It is used for stirring organic waste to realize

Get Price -

26 04 2024

26 04 2024Exploring Organic Fertilizer Tank Fermentation

Dec 15, 2023 · Fermentation for Organic Fertilizer Tanks. December 15, 2023. News. There are two types of organic fertilizer tanks: horizontal and vertical. Horizontal Fermentation Tank: The process begins by uniformly mixing collected manure in the fertilizer box and then pumping it into a dry-wet separation pretreatment machine within the system.

Get Price -

26 04 2024

26 04 2024In Vessel Composting Equipment | Fermentation Tank | Fast

Composting in vessel fermenter: when the moisture content of fertilizer materials reduce to about 50%, you can feed them into the fermentation tank. In only 7-15 days, the materials will decompose completely. Crushing: to make sure the composted organic fertilizer has uniform particle size, we equipped a crushing machine.

Get Price -

26 04 2024

26 04 2024Cheap Vertical Waste & Manure Fermentation Tank Compost

Vertical Waste & Manure Fermentation Tank has the characteristics of short fermentation period, cover small area and friendly environment.The closed aerobic fermentation tank is composed of nine systems: feed system, silo reactor, hydraulic drive system, ventilation system, discharge system, exhaust and deodorization system, panel and electronic control system.

Get Price

English

English

中文简体

中文简体