-

26 04 2024

26 04 2024Exploring Organic Fertilizer Tank Fermentation

Dec 15, 2023 · Fermentation for Organic Fertilizer Tanks. December 15, 2023. News. There are two types of organic fertilizer tanks: horizontal and vertical. Horizontal Fermentation Tank: The process begins by uniformly mixing collected manure in the fertilizer box and then pumping it into a dry-wet separation pretreatment machine within the system.

Get Price -

26 04 2024

26 04 2024Fermentation | Free Full-Text | Microbiological and

May 2, 2023 · Anaerobic digestion of animal manure results in the production of renewable energy (biogas) and nutrient-rich biofertilizer. A further benefit of the technology is decreased greenhouse gas emissions that otherwise occur during manure storage. Since animal manure makes anaerobic digestion cost-efficient and further advance the technology for higher methane yields, it is of utmost importance to

Get Price -

26 04 2024

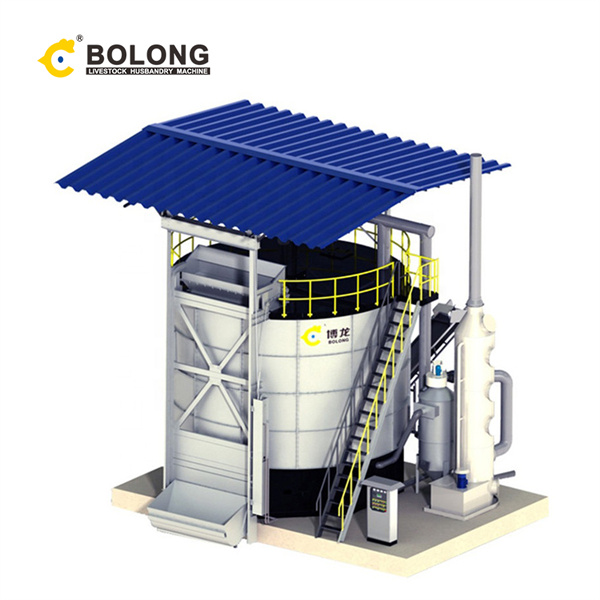

26 04 2024Bio Organic Fertilizer Fermentation Tank

1. High-temperature aerobic fermentation and bio-bacteria technology using with low energy consumption. 2. Closed fermentation, biological deodorization equipment to achieve no secondary pollution. 3. The device body made of stainless special materials to reduce corrosion and long life in Fermentation Tank for Cow Manure. 4.

Get Price -

26 04 2024

26 04 2024Fully Automatic Composting Machine Price|with 15-Day Fermentation

The moisture content should be controlled at 50%-75% during fermentation. High Temperature. 50-70℃ is the ideal temperature for aerobic reproduction. Our fully automatic composting machine can keep the temperature between 50℃-65℃ and last about 5 days. Abundance Oxygen.

Get Price -

26 04 2024

26 04 2024Livestock And Poultry Manure Fermentation Tank | Compost

Quality Test Before Delivery. Check Items When Packing. After-sale Service. The livestock and poultry manure fermentation tank can process animal manure and animal carcasses such as chickens, pigs, cattle, sheep, and horses. Its processing capacity is 2~5 cubic meters per day. Free inquiry now!

Get Price -

26 04 2024

26 04 2024Applied Sciences | Free Full-Text | Development and - MDPI

Jul 27, 2023 · Traditional cow manure composting equipment often lacks ventilation, heating, and real-time monitoring and adjustment capabilities, hindering manure maturation and proper utilization of compost, moisture reduction, and optimal environmental conditions for microbial activity.

Get Price -

26 04 2024

26 04 2024Manure Fermentation - Jongia Mixing Technology

The process involves the use of solid-state fermentation, where the manure is mixed with other organic wastes such as paper sludge and dried to a moisture content of 30-40%. The mixture is then loaded into fermentation tanks, where the fermentation process takes place.

Get Price -

26 04 2024

26 04 2024Industrial Fermentation Tank for sale for Fertilizer Plant

First you should calibrate the pH electrode and dissolved oxygen electrode. Fertilizer sterilization. Put the medium into the tank as needed. After sealed by the requirement, small fermentation tank (5 l) can be put the tank body in large sterilization pot sterilization (115 ℃, 30 minutes). A large fermentation tank (10 l and above) should

Get Price -

26 04 2024

26 04 2024Organic Fertilizer Production | Organic Fertilizer Machine

Specialize in Organic Fertilizer Production. ABC Machinery is a leading manufacturer of organic fertilizer production with CE & ISO certifications. We specializes in the design, development, and production of large-scale equipment such as fermentation tanks, and fertilizer granulators. ABC machinery provide customized solution for organic

Get Price -

26 04 2024

26 04 2024Organic Fertilizer Fermentation Tank | 3 Stages of Fermentation

There are four treatment procedure of the organic fertilizer fermentation tank. Firstly,automatically feeding.Then,you can make material get perfect stage through high-temperature fermentation. After that,material is discharged from your fermenter. Finally,you can put these fermented material into storage. organic tertilizer production tank.

Get Price -

26 04 2024

26 04 2024A Design of a Solar Fermentation System on Chicken Manure by

Nov 12, 2021 · The fermenter section is horizontally matched with a water tank and a stirring blade, and the manure and decomposing bacteria are placed therein for fermentation. The temperature control part is divided into a solar heating and a backup gas-fuel water heater to make the fermenter reach a constant temperature.

Get Price -

26 04 2024

26 04 2024manure fermentation tank – Shovel

Jan 5, 2022 · Also look at the upper tank, which should be constructed with waterproof materials, and it should also have an automatic bucket elevator and heat exchange system. After assessing all of the ones that you can find, you will eventually locate the very best animal manure fermentation tank for this exact purpose.

Get Price -

26 04 2024

26 04 2024Fermentation tank | Working princile and constructure of

The main structures of fermentation tank include body, mixer, air supply system, material lifting device, control cabinet, hydraulic power station, biological deodorization equipment and sensors of temperature and oxygen concentration. Mixer: The mixer is fixed inside the fermentation tank. It is used for stirring organic waste to realize

Get Price -

26 04 2024

26 04 2024Fermentation tank – DSS Instrument

Fermentation tank. 1 Introduction of fermentation tank. The manure high-temperature fermentation equipment is an intelligent integrated complete set of equipment for the treatment of organic waste such as livestock and poultry manure,kitchen waste, vegetable and fruits waste.

Get Price -

26 04 2024

26 04 2024Manure fermentation on farm scale in Bathmen - CCS Energie-advies

In reality the manure processing consists of three steps. The manure is first fermented. In fermentation, manure is brought into a heated tank, where bacteria break down a part of the biomass and produce biogas. The digestate is then separated into a thick and thin fraction. Finally, the thin fraction goes to the manure processing plant.

Get Price

English

English

中文简体

中文简体