-

07 05 2024

07 05 2024The anaerobic fermentation of food waste: a comparison of two

Oct 1, 2012 · The general idea to use food waste as a co-substrate for treating materials, whose biodegradability need improvement, can be confirmed by our examinations. Although in this study food waste (consisting of different waste kinds, see 2.1 Substrate) as single substrate was anaerobically digested, the results allow the mentioned assumption.

Get Price -

07 05 2024

07 05 2024Global Food Waste | SpringerLink

Jan 1, 2022 · Several countries have taken action to tackle the food waste problem with the goal to reach target 12.3. The report “SDG target 12.3 on food loss and waste: 2018 progress report” published in 2018 by the Champions 12.3, an international initiative established to accelerate progress toward target 12.3, presents a list of the countries setting strategies to reach target 12.3 (Champions 12.3

Get Price -

07 05 2024

07 05 2024Industrial fermentation processes | Alfa Laval

Industrial fermentation processes. Pioneering and commercializing new techniques to produce viable bio-based products through fermentation requires reliable, resource-efficient process equipment and knowledge of regulatory requirements. Our portfolio of heat exchangers, separators, membranes, evaporators and fluid handling equipment helps you

Get Price -

07 05 2024

07 05 2024Solid-state fermentation technology and innovation for the

Oct 14, 2020 · It has now passed more than forty years since solid-state fermentation (SSF) research developments have gained importance for the scientific community. After so many years, numerous processes and equipment for SSF were studied and designed focusing on the production of different commercially relevant bioproducts such as enzymes, fermented food, such as Chinese daqu and koji, organic acids

Get Price -

07 05 2024

07 05 2024Fermenters: History, Functions and Construction

The fermenter consisted of a large cylindrical tank with air introduced at the base via network of perforated pipes. In later modifications, mechanical impellers were used to increase the rate of mixing and to break up and disperse the air bubbles (Fig. 20.1). This process led to the compressed air requirements.

Get Price -

07 05 2024

07 05 2024Basic Fermenter Design : External, Agitation & Aeration

Basic Fermenter Design : External, Agitation & Aeration, Inlets and Outlets. De Becze and Liebmann (1944) used the first large scale (above 20 litre capacity) fermenter for the production of yeast. But it was during the First World War, a British scientist named Chain Weizmann (1914-1918) developed a fermenter for the production of acetone.

Get Price -

07 05 2024

07 05 2024A novel solid-state submerged fermenter (3SF) for acidogenic

Nov 1, 2023 · @article{Singh2023ANS, title={A novel solid-state submerged fermenter (3SF) for acidogenic fermentation of food waste at high volumetric loading: Effect of inoculum to substrate ratio, design optimization, and inoculum enrichment}, author={Virender Singh and Banu {\"O}rmeci and Ashutosh Singh and Swakar Saha and Abid Hussain}, journal={Chemical

Get Price -

07 05 2024

07 05 2024Bioreactor- Definition, Design, Principle, Parts, Types

May 7, 2023 · Bioreactor Definition. A bioreactor is a type of fermentation vessel that is used for the production of various chemicals and biological reactions. It is a closed container with adequate arrangement for aeration, agitation, temperature and pH control, and drain or overflow vent to remove the waste biomass of cultured microorganisms along with their products.

Get Price -

07 05 2024

07 05 2024An Overview of Fermenter and the Design Considerations to

The tower fermenter is an elongated non-mechanically stirred fermenter with aspect ratio of at least 6:1 for tubular section or 10:1 overall, through which there is unidirectional flow of gases. The tower fermenter used for citric acid production on a laboratory scale having height: diameter ratio of 16:1.

Get Price -

07 05 2024

07 05 2024Frontiers | Gas Fermentation—A Flexible Platform for

Jan 27, 2016 · Figure 1. Overview of feedstock and product options for gas fermentation. Feedstocks to the gas fermentation platform are highlighted in light blue (carbon and electron sources) and green (electron sources). Feedstocks shown are at various stages of commercial deployment.

Get Price -

07 05 2024

07 05 2024Current perspectives on acidogenic fermentation to produce

Abstract. Volatile fatty acids (VFAs) are key platform chemicals used in a multitude of industries including chemicals, pharmaceuticals, food and agriculture. The current route for VFA production is petrochemical based.

Get Price -

07 05 2024

07 05 2024Comprehensive review on agricultural waste utilization and

This review article presented the current status and traditional agricultural waste (livestock manure and crop straws) utilization , the art of aerobic fermentation process including ultrahigh temperature fermentation and composting.

Get Price -

07 05 2024

07 05 2024Sustainable Waste-to-Energy Technologies: Fermentation

Jan 1, 2018 · Waste bread: Continuous anaerobic fermentation using sludge: 109 mL/g FW Han et al. (2016b) Pineapple waste: Anaerobic mixed culture fermentation: 77.3 mL H 2 /g volatile solids: Reungsang (2013) Mixed fruit peel waste: Continuous fermentation using up-flow anaerobic contact filter: 42.8 mL H 2 /g FW d: Vijayaraghavan et al. (2007) Banana peels

Get Price -

07 05 2024

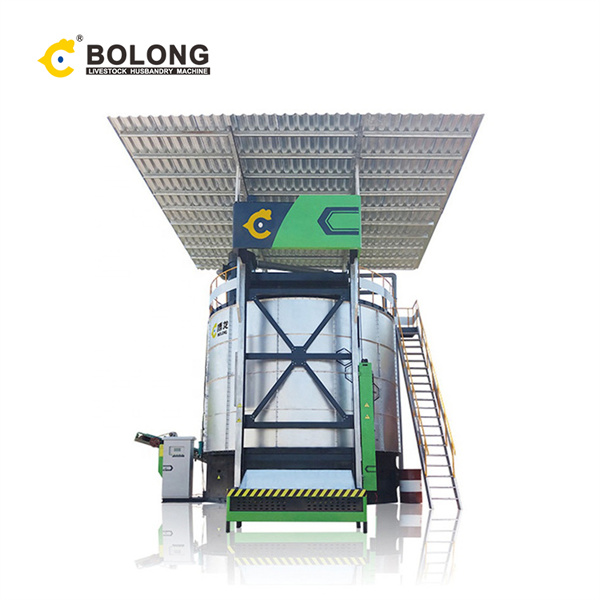

07 05 2024Organic Waste Fermenter Suppliers List - Global Sources

Organic Waste Fermenter Verified Business Types Manufacturer(3) Exporter(3) Importer(2) Agent(1) Consultant(1) Wholesaler(1)

Get Price -

07 05 2024

07 05 2024Bokashi Supplemental Fermenter - Bokashicycle LLC

Once the fermenter is filled completely you should allow a minimum of 7 days before placing the fermented product in the soil. Always mix it well with soil and cover with about 6 to 8 inches of soil for the moist rapid and efficient conversion to enriched soil. Use with bokashi culture mix as directed in the instructions for the food waste

Get Price

English

English

中文简体

中文简体