-

07 05 2024

07 05 2024What is Energy-Saving and High-Efficiency Manure-Treatment

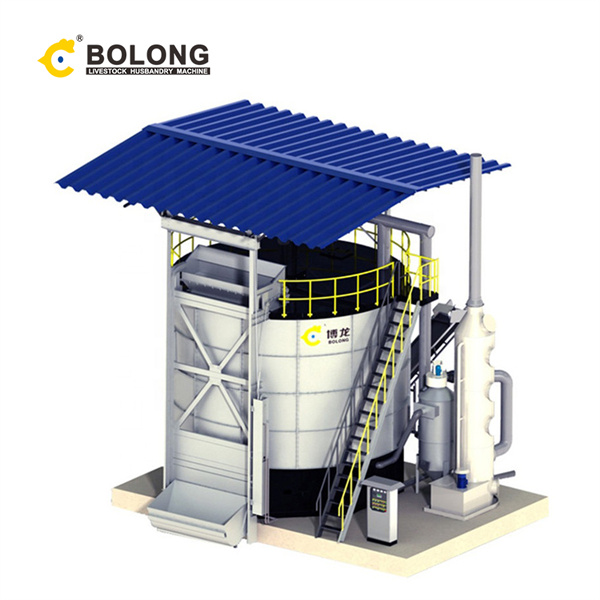

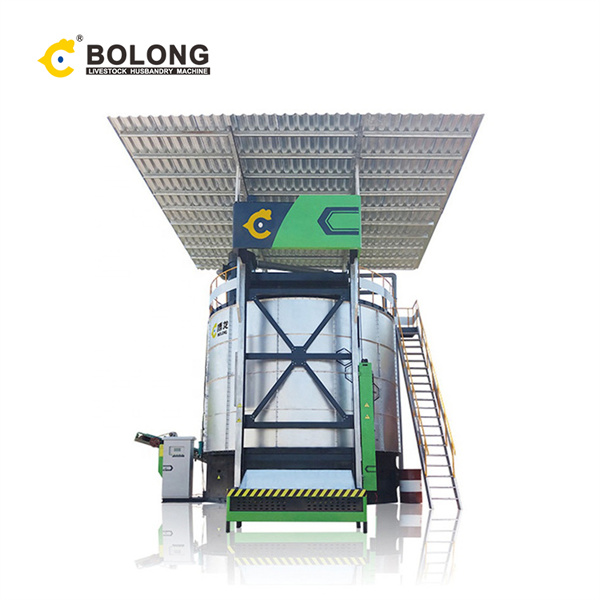

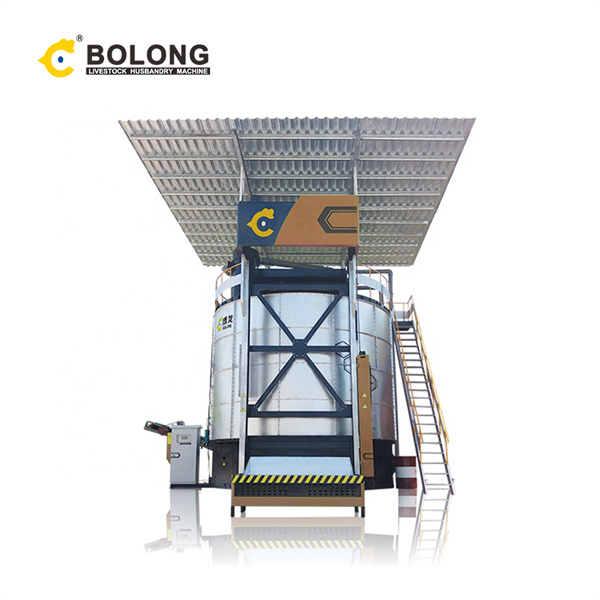

Home Video Channel What is Energy-Saving and High-Efficiency Manure-Treatment Fermentation Tank Sold Directly From The Factory Organic Fertilizer Fermentation Tank US$170,000.00-340,000.00 / Set

Get Price -

07 05 2024

07 05 2024Fermentation | Free Full-Text | Microbiological and

May 2, 2023 · Pre-treating animal manure to enhance hydrolysis can be dependent on the energy efficiency of the process as well as the complexity of the pre-treatment unit. For cattle manure, pretreatment can improve the biodegradability of the content of lignocellulose matter.

Get Price -

07 05 2024

07 05 2024Beer Fermentation Tanks - YoLong Brewtech

Jan 19, 2024 · Beer fermentation tanks cover a wide range of sizes from a few barrels to massive volumes over 1000 barrels. Some typical fermenter capacities include: Pilot Systems: 1-3 BBL. Microbreweries: 3-7 BBL, 7-30 BBL. Pub Breweries: 15-30 BBL. Production Breweries: 30-300 BBL, 600-800 BBL, 1000+ BBL.

Get Price -

07 05 2024

07 05 2024Exploring Organic Fertilizer Tank Fermentation

Dec 15, 2023 · Horizontal Fermentation Tank: The process begins by uniformly mixing collected manure in the fertilizer box and then pumping it into a dry-wet separation pretreatment machine within the system. After pretreatment, the manure enters the main machine for solid-liquid separation. Dry matter from the fermentation bucket continuously enters the

Get Price -

07 05 2024

07 05 2024Production of ethanol fuel via syngas fermentation

Jan 1, 2020 · Fig. 1 presents the conceptual process flowsheet to produce anhydrous ethanol from syngas, which consists of three main unit operations: (i) the syngas bioreactor (R-01); ethanol distillation (T-01 and T-02) to achieve azeotropic composition (also called hydrous ethanol); (iii) ethanol dehydration in molecular sieves (T-04 and T-05) to achieve 99.5% ethanol.

Get Price -

07 05 2024

07 05 2024Economic Perspectives of Biogas Production via Anaerobic

Jul 14, 2020 · Abstract. As the demand for utilizing environment-friendly and sustainable energy sources is increasing, the adoption of waste-to-energy technologies has started gaining attention. Producing biogas via anaerobic digestion (AD) is promising and well-established; however, this process in many circumstances is unable to be cost competitive with

Get Price -

07 05 2024

07 05 2024Bioenergy production from chicken manure: a review - Springer

Jun 12, 2023 · Here, we review the conversion of chicken manure into biomethane by anaerobic digestion with focus on limiting factors, strategies to enhance digestion, and valorization. Limiting factors include antibiotics, ammonia, fatty acids, trace elements, and organic compounds.

Get Price -

07 05 2024

07 05 2024Organic Fertilizer Fermentation Tank | 3 Stages of Fermentation

There are four treatment procedure of the organic fertilizer fermentation tank. Firstly,automatically feeding.Then,you can make material get perfect stage through high-temperature fermentation. After that,material is discharged from your fermenter. Finally,you can put these fermented material into storage. organic tertilizer production tank.

Get Price -

07 05 2024

07 05 2024Agricultural biogas plants in Poland: Investment process

Sep 1, 2012 · Experts are forecasting a dynamic development of agricultural biogas plants till 2020 at a rate of a few tens per cent a year [12], [13], [14].The highest amount of renewable energy obtained in Poland currently comes from solid biomass—85.4%, then from liquid biofuels—6.7%, from hydropower—3.6% and biogas—1.7% (Fig. 1) [15].

Get Price -

07 05 2024

07 05 2024economical and energy-efficient fertilizer fermentation tank

Fermented Leaf Fertilizers—Principles and Preparation 2019/8/6/ · Fermented foliar fertilizers, FFF (also known as fermented leaf fertilizers, FLF), describe anaerobically d

Get Price -

07 05 2024

07 05 2024Applied Sciences | Free Full-Text | Development and - MDPI

Jul 27, 2023 · Traditional cow manure treatment methodologies, including open-air composting [10,12], closed composting, and biogas fermentation, often results in odor interference, harmful gas generation, and low fertilizer efficiency. Recently, due to heightened environmental awareness and technological advancements, ventilation and heating of cow manure

Get Price -

07 05 2024

07 05 2024Commercial Fermentation Tanks - YoLong Brewtech

Feb 23, 2024 · Commercial fermentation tanks enable large-scale beverage production with capacities ranging from a few barrels to thousands of barrels. They are constructed from stainless steel or other approved materials that resist corrosion from acidic products. Tanks can be customized with accessories like temperature controllers, cooling jackets

Get Price -

07 05 2024

07 05 2024Using pig manure to promote fermentation of sugarcane

Mar 1, 2014 · The development of cost-effective and energy-efficient technologies for the stabilization of organic wastewater by microalgae has been essential and sought after. In the current study, GXU-A4 was isolated from an aerobic tank treating molasses vinasse (MV) and identified as Desmodesmus sp. based on its morphology, rbcL, and ITS sequences. It

Get Price -

07 05 2024

07 05 2024Exploring the environmental and economic potential - Springer

Jul 18, 2021 · The design of SGEPM had an additional fermentation tank for producing biogas from swine manure during the three-stage wastewater treatment system, then introducing biogas into the electricity generator to generate electricity for energy recovery.

Get Price -

07 05 2024

07 05 2024Efficient chicken manure fermenting agent and preparation

Jun 5, 2013 · When ℃, add chicken manure starter according to the ratio of 0.2%. After the mixture is fully mixed, it is placed in a fermentation tank to ferment for 20 days. Detect the nutritional components, pH value, and bacterial content of chicken manure before and after fermentation. At the same time, a blank control test was performed.

Get Price

English

English

中文简体

中文简体