-

09 05 2024

09 05 2024Harnessing the power of cow dung: Exploring the environmental

Dec 1, 2023 · The energy cost of producing biogas is 0.06 USD per kWh if the methane concentration utilized is 60–70% [41]. According to techno-economic analysis from Obileke et al., the energy cost for biogas generation is USD 0.078 per kWh for a production scale of 9000 kg of cow dung per month [42]. According to Sustainable Conservation in 2019, the

Get Price -

09 05 2024

09 05 2024Comprehensive review on agricultural waste utilization and

This review article presented the current status and traditional agricultural waste (livestock manure and crop straws) utilization , the art of aerobic fermentation process including ultrahigh temperature fermentation and composting.

Get Price -

09 05 2024

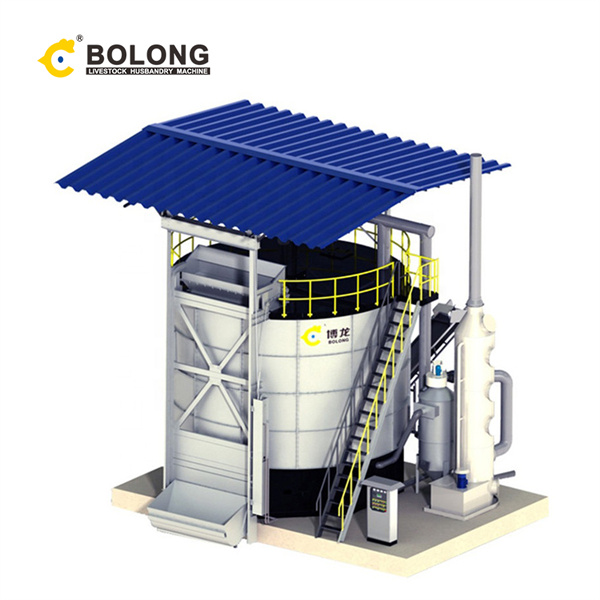

09 05 2024In Vessel Composting Equipment | Fermentation Tank | Fast

Composting in vessel fermenter: when the moisture content of fertilizer materials reduce to about 50%, you can feed them into the fermentation tank. In only 7-15 days, the materials will decompose completely. Crushing: to make sure the composted organic fertilizer has uniform particle size, we equipped a crushing machine.

Get Price -

09 05 2024

09 05 2024Recent advances on organic biofertilizer production from

Aug 2, 2022 · Additionally, content of phosphorus and potassium are also found to be high in food wastes based bio-fertilizers. It has been concluded that nutrient contents of the bio-fertilizer produced is mainly depends on the type of food wastes used for the production of bio-fertilizer (Rossi et al., 2016). Additionally, co-digestion of these food wastes

Get Price -

09 05 2024

09 05 2024Exploring Organic Fertilizer Tank Fermentation

Dec 15, 2023 · Horizontal Fermentation Tank: The process begins by uniformly mixing collected manure in the fertilizer box and then pumping it into a dry-wet separation pretreatment machine within the system. After pretreatment, the manure enters the main machine for solid-liquid separation. Dry matter from the fermentation bucket continuously enters the

Get Price -

09 05 2024

09 05 2024Construction of an economical Xylose-utilizing Saccharomyces

The resulting S. cerevisiae strain ABX0928-0630 exhibits a rapid growth rate and possesses near 100% xylose utilization efficiency to produce ethanol with industrial material. Pilot-scale fermentation indicated the predominant feature of ABX0928-0630 for industrial application, with ethanol yield of 0.48 g/g sugars after 48 hours and volumetric

Get Price -

09 05 2024

09 05 2024Commercial Fermentation Tanks - YoLong Brewtech

Feb 23, 2024 · Commercial fermentation tanks enable large-scale beverage production with capacities ranging from a few barrels to thousands of barrels. They are constructed from stainless steel or other approved materials that resist corrosion from acidic products. Tanks can be customized with accessories like temperature controllers, cooling jackets

Get Price -

09 05 2024

09 05 2024Horizontal Fermentation Tank - TongDa

Mar 28, 2023 · This tank is designed to provide a controlled environment for the decomposition of a wide range of organic materials, including animal manure, crop residue, food waste, and more. With its large capacity and efficient mixing system, our Horizontal Fermentation Tank can process large volumes of material quickly and effectively. Built with high

Get Price -

09 05 2024

09 05 2024Steel Tank Fermentation: Advantages in Modern Winemaking

Jan 10, 2024 · Efficient water use in steel tank fermentation does not only contribute to environmental protection, but it also reflects on the industry’s commitment to sustainable practices. While not directly quantified here, your understanding of water efficiency is essential when considering the sustainability of steel fermentation tanks.

Get Price -

09 05 2024

09 05 2024High-Temperature Aerobic Fermentation Tank | Fermentation Tank

The High-temperature aerobic fermentation tank equipment developed by ABC Machinery adopts a fully enclosed design. The fecal fermentation process is not affected by the natural environment, allowing the production of organic fertilizer to meet industrial production standards, preventing the leakage of waste gas generated by fermentation, and eliminating secondary pollution of waste gas

Get Price -

09 05 2024

09 05 2024Production of ethanol fuel via syngas fermentation

Jan 1, 2020 · Fig. 1 presents the conceptual process flowsheet to produce anhydrous ethanol from syngas, which consists of three main unit operations: (i) the syngas bioreactor (R-01); ethanol distillation (T-01 and T-02) to achieve azeotropic composition (also called hydrous ethanol); (iii) ethanol dehydration in molecular sieves (T-04 and T-05) to achieve 99.5% ethanol.

Get Price -

09 05 2024

09 05 2024Organic Fertilizer Fermentation Tank | 3 Stages of Fermentation

There are four treatment procedure of the organic fertilizer fermentation tank. Firstly,automatically feeding.Then,you can make material get perfect stage through high-temperature fermentation. After that,material is discharged from your fermenter. Finally,you can put these fermented material into storage. organic tertilizer production tank.

Get Price -

09 05 2024

09 05 2024Industrial Fermentation Tank for sale for Fertilizer Plant

First you should calibrate the pH electrode and dissolved oxygen electrode. Fertilizer sterilization. Put the medium into the tank as needed. After sealed by the requirement, small fermentation tank (5 l) can be put the tank body in large sterilization pot sterilization (115 ℃, 30 minutes). A large fermentation tank (10 l and above) should

Get Price -

09 05 2024

09 05 2024Organic Fertilizer Production | Organic Fertilizer Machine

Specialize in Organic Fertilizer Production. ABC Machinery is a leading manufacturer of organic fertilizer production with CE & ISO certifications. We specializes in the design, development, and production of large-scale equipment such as fermentation tanks, and fertilizer granulators. ABC machinery provide customized solution for organic

Get Price -

09 05 2024

09 05 2024Fermentation - Wikipedia

Fermentation in progress: carbon dioxide bubbles form a froth on top of the fermentation mixture. Fermentation is a metabolic process that produces chemical changes in organic substances through the action of enzymes. In biochemistry, it is broadly defined as the extraction of energy from carbohydrates in the absence of oxygen.

Get Price

English

English

中文简体

中文简体