-

22 11 2024

22 11 2024The Mixed Fermentation Technology of Solid Wastes of

Apr 15, 2020 · College of Water Conservancy, Shenyang Agricultural University, Shenyang, China; Due to the large quantity and wide range of solid wastes of the biomass, and the dual characteristics of pollution and resource utilization, the energy utilization of anaerobic fermentation can promote its pollution control, so the mixed fermentation technology of solid wastes of agricultural biomass was studied.

Get Price -

22 11 2024

22 11 2024Anaerobic fermentation of organic solid waste: Recent updates

Sep 15, 2023 · Simultaneously, the anaerobic biorefinery process with multiple product co-production is sorted out. Product co-production can reduce waste discharge, enhance resource recovery efficiency, and serve as a model for improving anaerobic fermentation economics.

Get Price -

22 11 2024

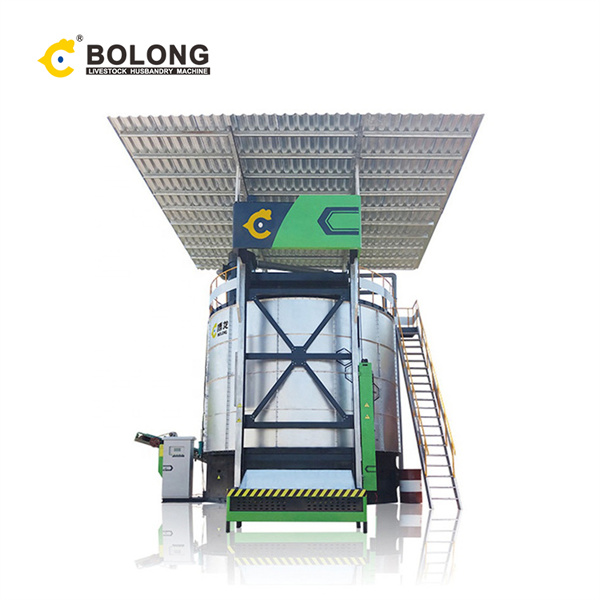

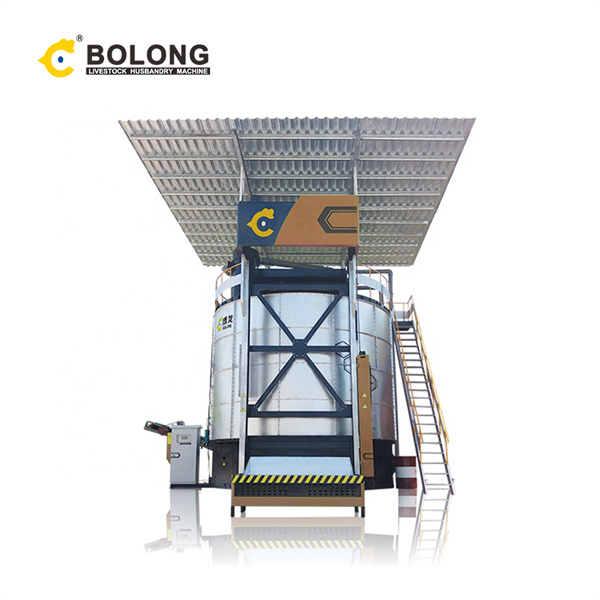

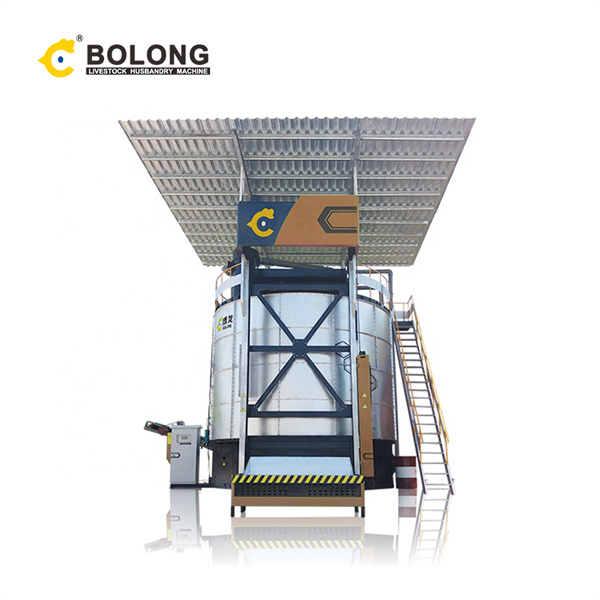

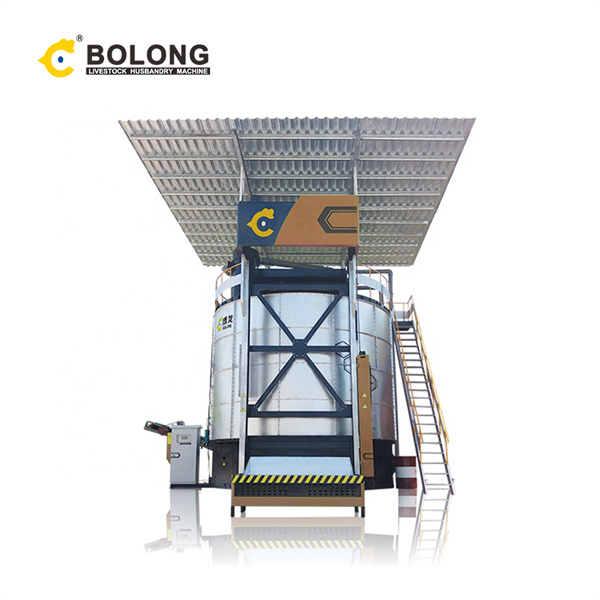

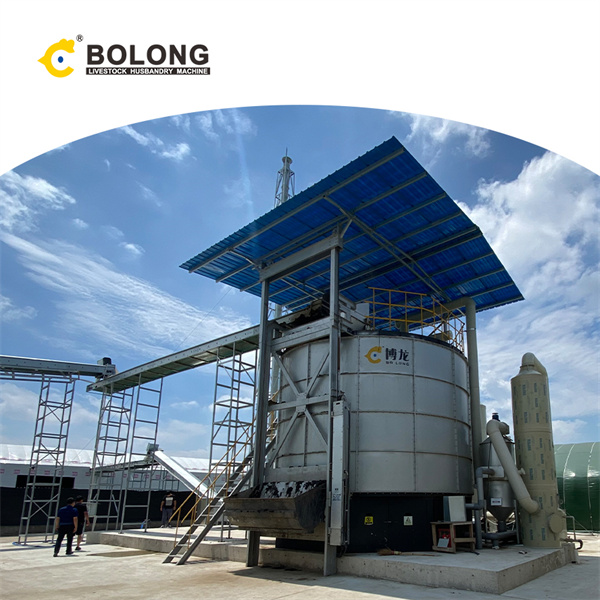

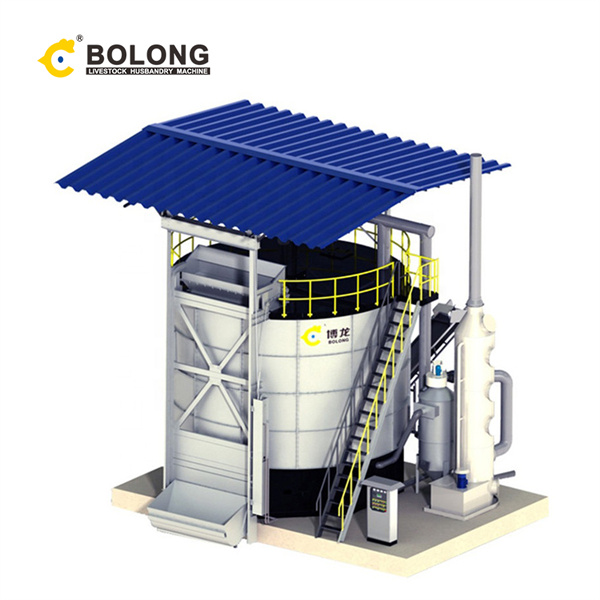

22 11 2024High-Temperature Aerobic Fermentation Tank | Fermentation Tank

The High-temperature aerobic fermentation tank equipment developed by ABC Machinery adopts a fully enclosed design. The fecal fermentation process is not affected by the natural environment, allowing the production of organic fertilizer to meet industrial production standards, preventing the leakage of waste gas generated by fermentation, and eliminating secondary pollution of waste gas

Get Price -

22 11 2024

22 11 2024CN106701563A - Full-automatic control multifunctional solid

The invention discloses a full-automatic control multifunctional solid-state fermentation tank, comprising a round vertical fermentation tank main body and a fermentation control system, wherein a loading auger is arranged at one side of the upper end of the fermentation tank main body; multiple clapboards are arranged in the fermentation tank main body; a high-material-bed material level

Get Price -

22 11 2024

22 11 2024How Does The Organic Fertilizer Fermentation Tank Work?

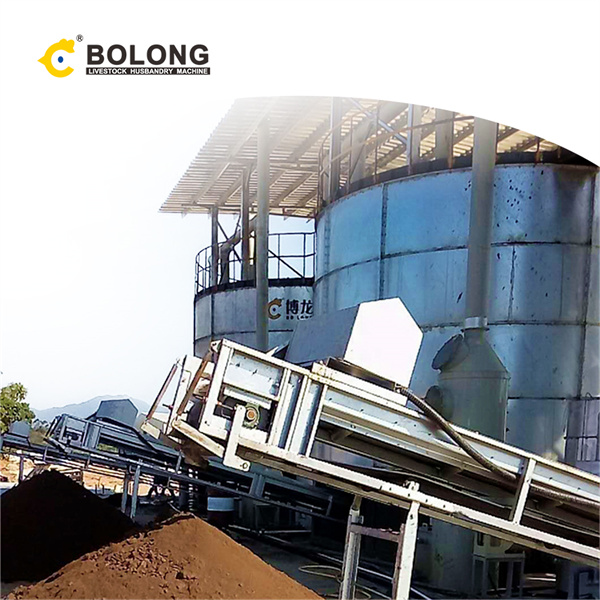

Fermentation tanks are used to efficiently process and recycle organic waste, reducing landfill usage and mitigating the environmental impact of waste disposal. Composting Facilities : Commercial composting facilities utilize large-scale fermentation tanks to process significant volumes of organic waste, which can include municipal green waste

Get Price -

22 11 2024

22 11 2024Cleaning and Sanitizing Your Fermentation Tank: Best Practices

Dec 29, 2022 · Sanitizing your fermentation tank is an essential step in preventing contamination and ensuring the quality of your finished product. There are a variety of that can be used to sanitize a fermentation tank, including using chemicals or heat. Chemical Sanitization. One method of sanitizing a fermentation tank is through the use of chemicals.

Get Price -

22 11 2024

22 11 2024An Urban-circular Ecosystem in Which Food Waste from a

First, the organic waste (biostock) is homogenized in a conditioning tank. It then undergoes a fermentation process using methanogens in a fermentation tank, and biogas is extracted as a renewable energy source.

Get Price -

22 11 2024

22 11 2024Advanced Organic Fertilizer Fermentation Tank for Sale

Middle Part: Include double-layer heat insulation tank, automatic control system, export device, etc. The inner wall of the tank is lined with 304 stainless steel plate, which can effectively prolong the service life of the fermentation tank and reduce the residue of rotten clinker.

Get Price -

22 11 2024

22 11 2024(PDF) Advanced Fermentation Techniques for Lactic Acid

Aug 17, 2023 · Fermentative production of lactic acid from non-food-competing agricultural waste could reduce the cost of lactic acid production while addressing environmental concerns.

Get Price -

22 11 2024

22 11 2024Automatic tank cleaning systems,fermentation tank cleaning

Technical information: 1. This system can be used for tanks to diameter 2-15m. 2. Rated flow rate 10-12m3/hr, rated head 100 meters (pressure 10-15 bar)

Get Price -

22 11 2024

22 11 2024Foaming of rhamnolipids fermentation: impact factors and

Mar 29, 2021 · Rhamnolipids have recently attracted considerable attentions because of their excellent biosurfactant performance and potential applications in agriculture, environment, biomedicine, etc., but severe foaming causes the high cost of production, restraining their commercial production and applications. To reduce or eliminate the foaming, numerous explorations have been focused on foaming factors

Get Price -

22 11 2024

22 11 2024Future Trends in Fermentation Tank Technology--Fermentation

The technology behind fermentation tanks is continually evolving, driven by advancements in engineering, automation, and environmental sustainability. This article explores the future trends in fermentation tank technology and how these innovations will shape the organic waste management industry.

Get Price -

22 11 2024

22 11 2024The Design of Automatic Batching Device for Anaerobic

Jan 1, 2021 · Co-digestion in anaerobic fermentation has been widely used to improve biogas production. The biogas production from co-digestion of glucose and glycerol was studied in laboratory-scale batch

Get Price -

22 11 2024

22 11 2024Palm Oil Mill Effluent Treatment Processes—A Review - MDPI

Apr 22, 2021 · Ponding system or land application techniques are widely used at industrial scale to treat palm oil mill effluent (POME) prior to discharge to the environment. POME is considered as one of the major problems that has generated voluminously from the palm oil industries. The main purpose of this article is to organize the scattered available information on various aspects and a wide range of

Get Price -

22 11 2024

22 11 2024Fully automatic composting machine | working process

What kinds of waste can SEEC automatic compost machine be adopted? SEEC automatic compost machine is available for various organic waste. And the specific raw materials include: Agricultural waste: Straw, rice hull, corn straw and so on; Animal waste: manure from poultry and livestock, bat guano; Other waste: sawdust, soybean meal and so on.

Get Price

English

English

中文简体

中文简体